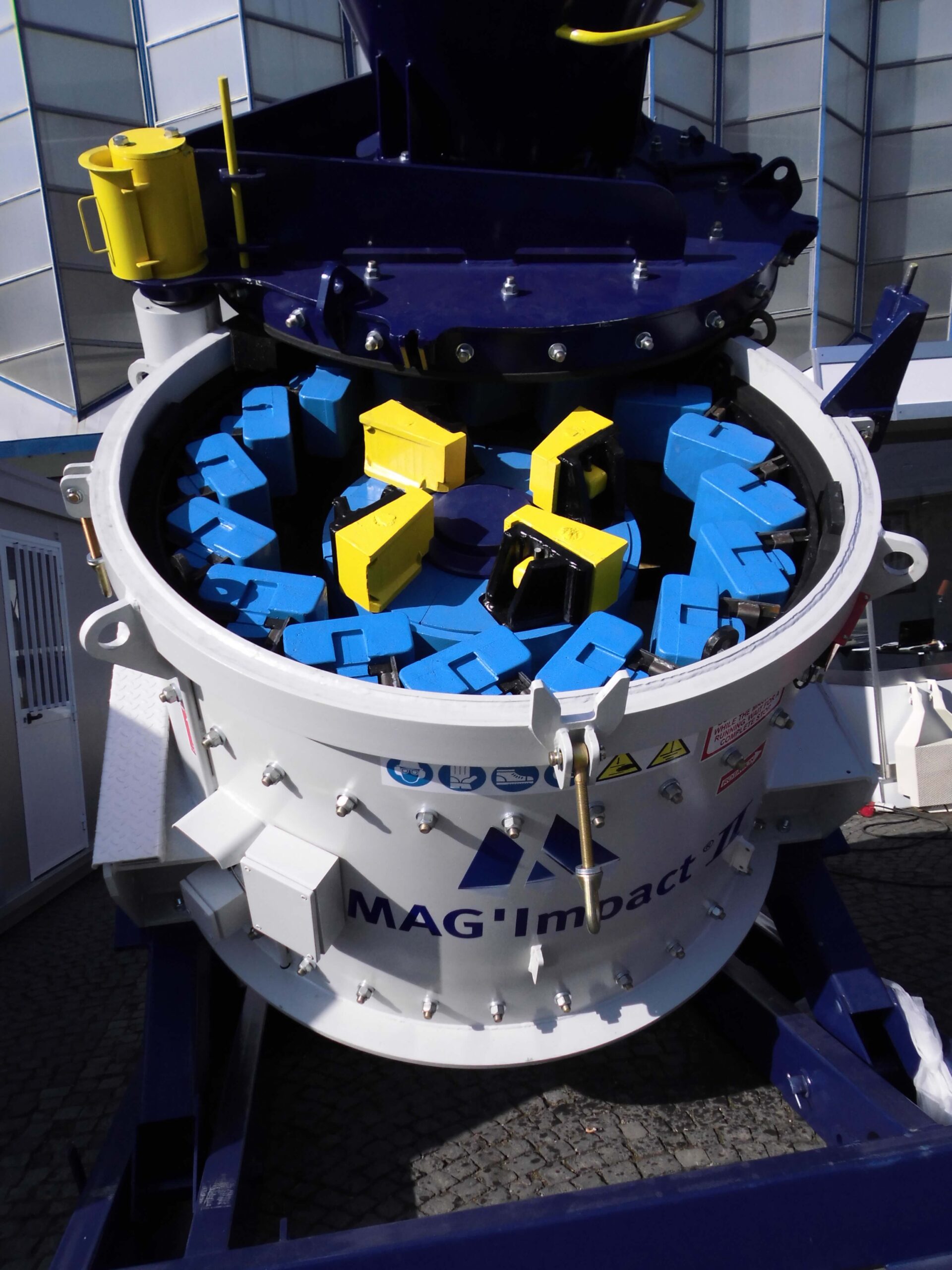

With MAGOTTEAUX we supply 4 models of VSI crusher

Magotteaux produces 4 models of vsi crusher depending on the capacity needed and size of the feed material to be crushed. One model of the VSI crusher is designed to manufacture sand for ready mixed concrete. Each of these has a different diameter, motor and various other parts to cover a variety of needs in the crushing industry and to cater for different feed sizes.

Mag’ Impact 2100

4 Shoe Table, Anvil Ring, Hydraulic Group, Control Panel, Pulleys/Belts, 1 Base for Motor.

Mag’Impact 2400

5 Shoe Table, Anvil Ring, Hydraulic Group, Control Panel, Pulleys/Belts,1 Base for Motor.

Mag Impact 2100 Sand

6 Shoe Table, Anvil Ring, Hydraulic Group, Control Panel, Pulleys/Belts, 1 Base For Motor

Mag’Impact 2700

4 Shoe Table, Anvil Ring, Hydraulic Group, Control Panel, Pulleys/Belts, 2 Bases For Motor

High-quality

finished products

- Impact crushing offers outstanding cubicity

to the produced gravel, crushed stone and

manufactured sand. - The way in which the materials are driven

towards the anvils increases the percentage of

broken edges in the finished products. - The mechanical properties of the finished

products are thus improved.

How Does A Vertical Shaft Impact Crusher Work?

1

The material to be crushed is fed through the feed hopper.

2

It then falls onto the center of the rotating table.

3

The ejectors impellers (on the table) drive the particles towards the anvils located on the outer ring.

4

A wide range of impeller/anvil designs are available to suit your different materials and applications.

Flexible VSI Crusher

The versatility of our VSI’s mean that it can be easily adapted to different jobs.

Versatile Working Environment

Stationary, semi-mobile or mobile (track-mounted)

User Control

Different reduction coefficient ratios can be set by the user by altering the speed of the table

High Level of Throughput

Throughput: 80 t/h -> 450 t/h

(depending on the model)

Reduced Wear Related Costs

We have developed metallurgical solutions (white iron

chromium alloys) and the Metal Matrix Composite

(MMC). These solutions are suitable for medium to high

abrasiveness in gravel pits and quarries. They increase

the life of wear parts.

FAQ

About MAGOTTEAUX vertical shaft impact crusher.

Common Uses for VSI’s?

A VSI crusher, or to give it its full name, a vertical shaft impact crusher, can be used for most crushing applications. The principal uses will be in quarries and gravel pits to produce products for roads and asphalt, ballast, manufactured sand for concrete and aggregates for use in the construction industry. But VSIs are also used for the recycling of building material, namely concrete and asphalt and the processing of steel slag. Increasingly in a conservation-conscious world, industries must learn to recycle used materials instead of dumping them. And this in itself can be a profitable industry if they are processed properly with the right machinery.

VSIs are commonly used to manufacture high quality aggregates used to build bridges, buildings, and tunnels for example..

Benefits of Using a VSI Crusher?

Versatile and Efficient: The VSI crushes hard and brittle materials with ease. It is the right choice for handling rock, cement clinker, ores, minerals, concrete, asphalt and other materials. As a crusher for building and road-making, the VSI is highly suitable.

Durable: During operation, rocks can fall into the bottom of the VSI. It forms a protective layer that increases the machine’s durability. The crusher’s main shaft uses calibrated rolling bearings for increased stability and reliability. This feature may also reduce your maintenance expenses.

Impact crushing also offers outstanding cubicity to the produced gravel, crushed stone and manufactured sand

Are They Hard To Maintain?

Mag’Impact has been designed to streamline maintenance operations, as well as limiting downtime (number and duration) thanks to: – easy opening of the cover lid to facilitate access to worn parts – easy and quick replacement of the main parts (ejectors impellers, anvils, etc.) – automated bearing lubrication

How Can I Hear More Information About The MAGOTTEAUX VSI Range?

Contact Southern Crusher Spares Today!!

+353 86-271-7109

gearoid@southerncrusherspares.ie

Check Out Our VSI’s In Action