The Exclusive Irish Dealer for Maggateux Wear Parts

Magotteaux: The Best Crushing Hammers on the Market – Now Available in Ireland

At Southern Crusher Spares Ltd, we are proud to announce that we are the exclusive Irish dealer for Magotteaux, the global leader in high-performance crushing hammers. With Magotteaux’s industry-leading products now in stock, we are excited to bring the best hammer technology ever developed to our customers across Ireland.

What Makes  Different

Different

Maggateux hammers stand out due to their advanced alloy composition, which is specifically engineered for superior wear resistance and durability compared to traditional materials like manganese steel. They are designed for enhanced performance in demanding applications, offering a longer lifespan and reduced downtime. Additionally, Maggateux hammers can be customized to meet specific crushing needs, ensuring optimal efficiency and output. Their combination of high-quality materials, innovative design, and the ability to tailor specifications sets them apart in the market for crusher wear parts.

Results To Expect

Durability and Performance: Maggateux parts are crafted from high-quality materials, built to handle tough conditions and last longer. This means fewer replacements and less downtime, keeping your operation on track.

Boosted Efficiency: With Maggateux, you’ll experience improved crusher performance, with optimized output and better overall productivity. Our parts minimize wear, helping your equipment run at peak efficiency.

Lower Maintenance Costs: By choosing Maggateux, you reduce the need for frequent maintenance, cutting both planned and unplanned downtime, and lowering your overall operational expenses.

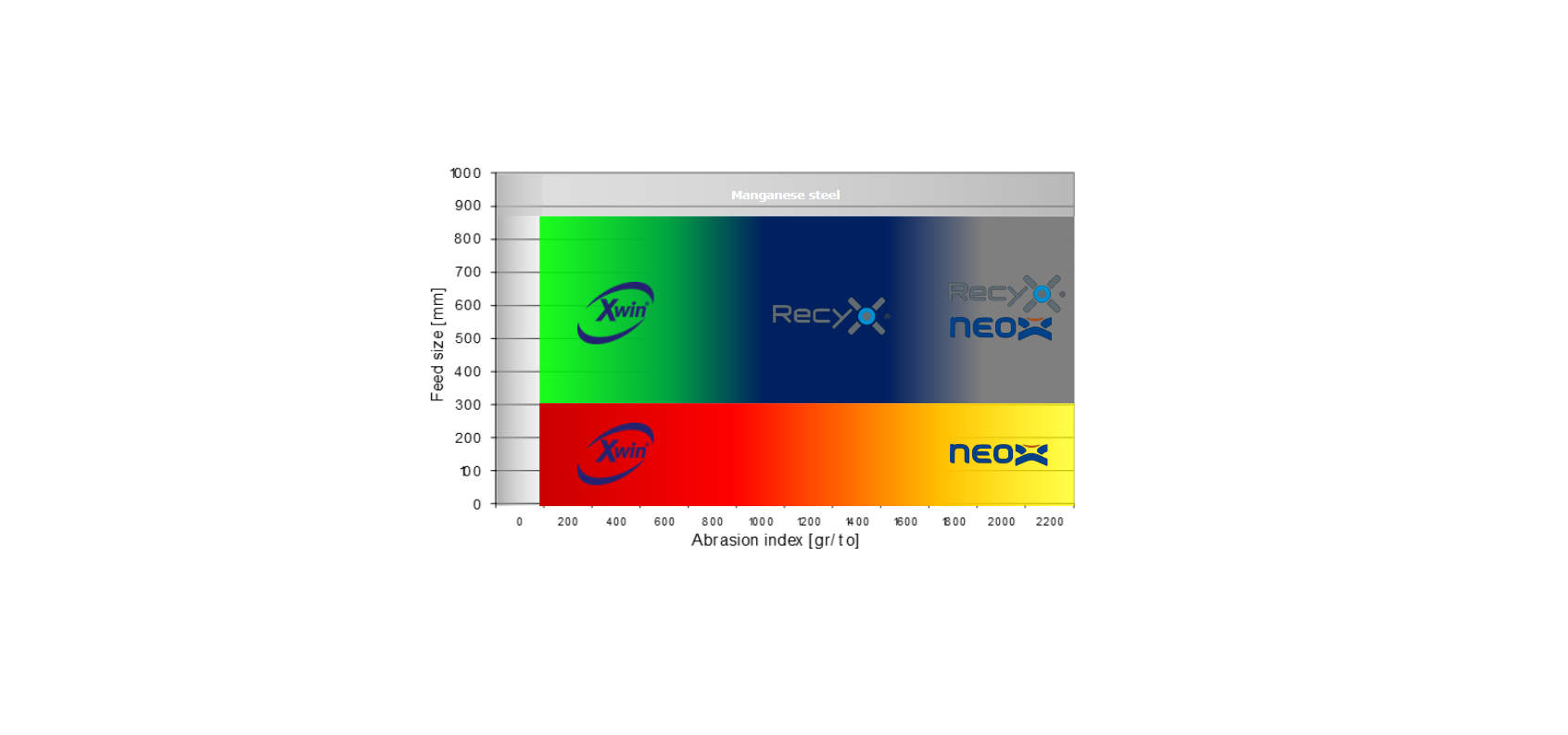

Choosing the Right Magotteaux Hammer: Understanding Feed Size and Abrasion Index

At Southern Crusher Spares Ltd, we are proud to stock a full range of Magotteaux hammers designed for a wide array of crushing applications. These hammers—RecYx, NeoX, Xwin Martensitic, and Xwin White Iron—are renowned for their superior wear resistance and performance. Each hammer is engineered to meet the unique demands of specific operational environments, helping you maximize efficiency, minimize wear, and reduce downtime.

Feed Size and Abrasion Index: What Do They Mean?

Feed Size (Y-axis): This refers to the size of the material being fed into the crusher. Larger feed sizes require more robust hammers to handle the increased impact and wear.

Abrasion Index (X-axis): This is a measure of how abrasive the material is. A higher abrasion index means that the material is more likely to cause wear and tear on the hammer, requiring tougher, more wear-resistant materials.

Selecting Your Hammer.

Each of Magotteaux’s hammer lines is designed to handle specific ranges of feed size and abrasion index. Here’s how each hammer fits into the equation:

RecyX

Best for: Medium feed sizes and moderate to high abrasion.

Application: Ideal for recycling applications, the RecYx hammer is designed to withstand abrasive materials such as concrete, asphalt, and other construction debris. It offers high impact resistance and wear life, making it perfect for crushing recycled materials with moderate to high abrasion.

NeoX

Best for: Large feed sizes and high abrasion.

Application: The NeoX hammer is built to handle large feed sizes while resisting wear from highly abrasive materials like quartz or granite. It’s an excellent choice for primary crushers where both impact and abrasion resistance are crucial. NeoX combines hardness and toughness, resulting in an extended lifespan under harsh conditions.

Xwin Martensitic

Best for: Small to medium feed sizes with low to medium abrasion.

Application: The Xwin Martensitic hammer is optimal for applications where the feed material is smaller and less abrasive. It’s commonly used in secondary and tertiary crushers, where precision and durability are key. This hammer’s martensitic steel composition gives it a balanced mix of wear resistance and impact strength.

Xwin White Iron

Best for: Small feed sizes and low abrasion.

Application: If you’re processing less abrasive materials like limestone or coal, the Xwin White Iron hammer is the best option. It is specifically designed for applications that require minimal abrasion resistance but still need strong impact durability. The white iron composition makes it suitable for low-abrasion environments while delivering great cost-effectiveness.

Proven Durability and Performance

Here What Our Customers have to say about our Magotteaux Hammers

“The reduction in downtime dramatically effected our yield, i wouldn’t bother with any other hammer”- ******

Kleeman 110 Evo

“I have never seen a hammer last as long in a machine”- ******

Metso 1213

“The ceramic inlay makes all the difference compared to regular manganese”- *****

Sandvik QI341

Any Questions?

Frequently Asked Questions about Maggateux Hammers

Whats The Difference Between A Manganease & Maggateux hammer?

Manganese Hammers

- Material: Constructed from high manganese steel (12-14% manganese), providing basic wear resistance.

- Durability: Known for toughness but limited in performance, making them less effective against hard and abrasive materials over time.

- Applications: Commonly used in mining, quarrying, and recycling but may struggle in demanding conditions.

- Cost-Effectiveness: Requires frequent replacements in high-impact situations, leading to higher long-term operational costs.

Maggateux Hammers

- Material: Made from proprietary advanced alloys, offering significantly enhanced performance and durability.

- Performance: Engineered for a longer lifespan and reduced downtime, maximizing efficiency even in the most challenging environments.

- Applications: Ideal for recycling, aggregate production, and other demanding applications where reliability is crucial.

- Customization: Tailored to specific crushing needs, ensuring optimal output and performance for various materials.

Key Differences

Cost Efficiency: Although Maggateux hammers may have a higher initial investment, they ultimately lead to lower operational costs and greater value over time due to their enhanced durability and performance.

Engineering Superiority: Maggateux hammers utilize advanced materials and innovative designs, while manganese hammers are traditional and less specialized.

Lifespan and Reliability: Maggateux hammers consistently outperform manganese hammers, offering superior longevity and reduced maintenance.

What Are Maggateux Hammers Made From?

Maggateux hammers are made from proprietary advanced alloys specifically engineered for enhanced performance and durability. These materials are designed to withstand harsh working conditions and provide superior wear resistance compared to traditional materials like manganese steel. The exact composition of these alloys can vary, but they generally include high-quality components that optimize toughness, impact resistance, and overall performance, ensuring longer lifespan and reduced downtime in crushing operations.

Where Are They Made?

Maggateux hammers are made in France

Can Maggateux hammers be customized for specific applications?

Yes, Maggateux hammers can be customized to meet the specific needs of different applications. We at Southern Crusher Spares work closely with customers to understand their crushing requirements and material characteristics. This allows us to tailor the design, size, and material composition of the hammers for optimal performance, ensuring they provide the best possible results in various environments, including recycling, aggregate production, and mining. Customization helps improve efficiency and prolong the lifespan of the hammers, making them an ideal choice for diverse operational needs.

The History Of Magotteaux

Continuously Pioneering Advanced Crushing Technology.

1967

The Beginning

Lucien Magotteaux, a civil engineer, buys a small iron foundry located in Vaux-sous-Chèvremont, Belgium.

- Birth of Magotteaux: Marked the creation of a future global leader in wear solutions.

- Strategic Growth: Started small, grew into a leader in impact-resistant alloys.

- Technological Leadership: Laid the foundation for leadership in crushing and wear technology.

1967

Changing The Game

High-chromium grinding media, successfully changed the standard for the whole cement industry.

- Industry Innovation: Introduced high-chromium media, revolutionizing grinding efficiency.

- Improved Performance: Set a new standard for durability and wear resistance in cement grinding.

- Energy Efficiency: Reduced energy consumption in cement production through enhanced grinding processes.

- Cost Savings: Helped lower operational costs by extending the lifespan of grinding media.

- Global Impact: Transformed practices industry-wide, becoming the benchmark for cement grinding.

1990

Evolving Past The Competition

Xwin® The first composite material (Metal Matrix Composites, MMC) technology developed by Magotteaux combining an increased resistance to both wear and shocks

- Pioneering Technology: Xwin® introduced the first Metal Matrix Composites (MMC) for enhanced performance.

- Superior Wear Resistance: Significantly increased durability in high-wear applications.

- Shock Absorption: Combined resistance to both wear and impact, improving equipment lifespan.

- Innovative Material: Set a new standard in composite material technology for industrial use.

- Magotteaux Leadership: Reinforced Magotteaux’s position as a leader in wear solutions.

2011

Global Quality Leader

Neox® New generation ceramic technology

- Advanced Innovation: Neox® represents the latest generation in ceramic technology.

- Enhanced Durability: Provides superior wear resistance for longer equipment life.

- Cutting-Edge Material: Combines ceramic strength with advanced engineering for tough conditions.

- Improved Performance: Designed to boost efficiency in demanding industrial environments.

- Leading Ceramic Solution: Sets a new benchmark for high-performance industrial ceramics.